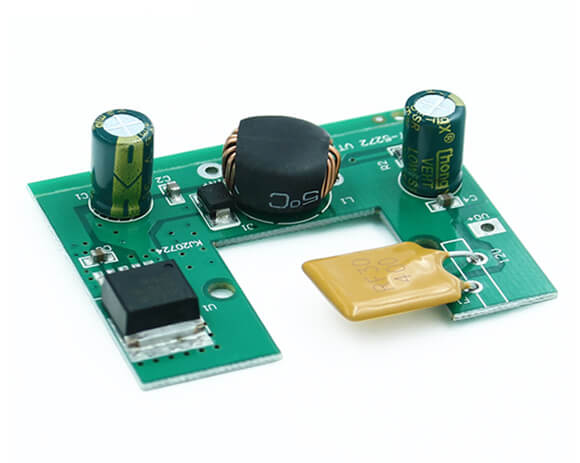

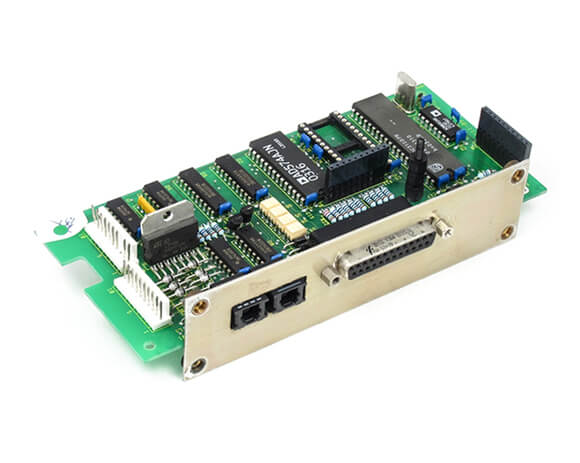

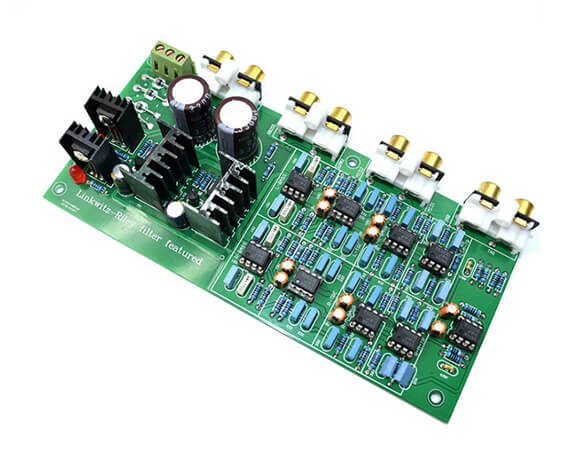

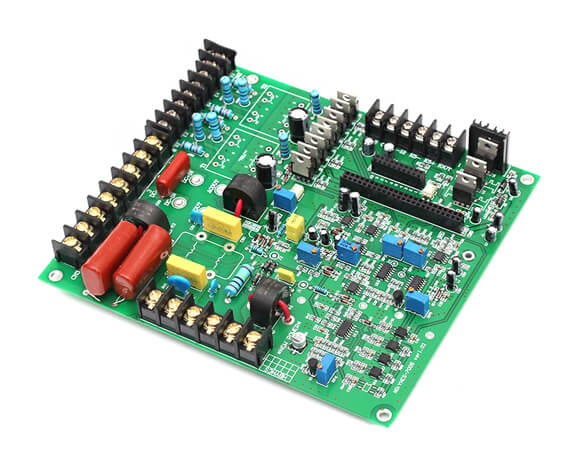

Custom Security Alarm Smoke Detector PCB Supplier

Key Features:

- High Density

- High Reliability

- Designability

- Productivity

- Testability

When you need high precision security PCB, please ask us for help. Because we specialize in a full-service PCB manufacturer. A leading PCB service and EMS service company that meets the rapid development of the world.

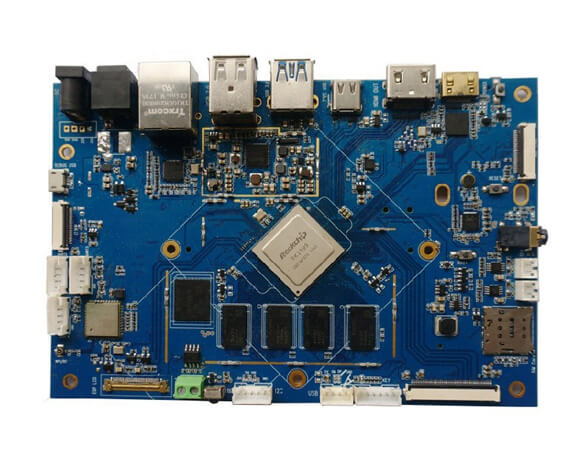

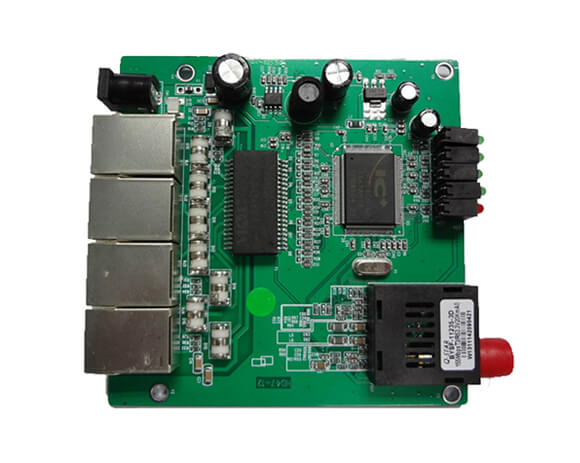

Detector PCB Application

Widely used in Large, Medium, and Small Projects.

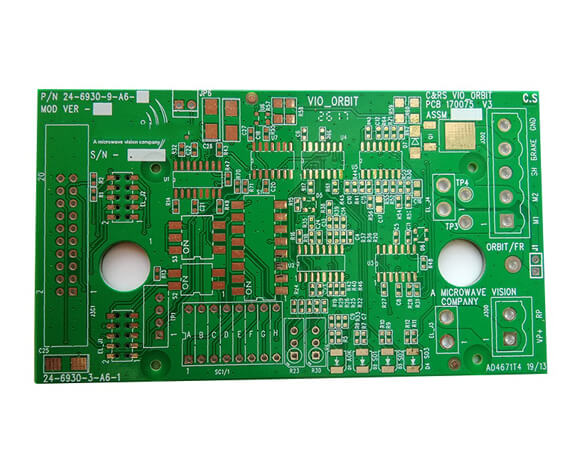

Detector PCB Specification

| Layers | 1-24 layers |

| Base Material | FR4, aluminum, Rogers, CEM-3 |

| Board Thickness | 1.6mm |

| Copper Thickness | 0.5-3oz |

| Surface Finishing | HAL, HASL(LF), ENIG, OSP |

| Solder Mask Color | Green / LED driver circuit board |

| Min. Line Width | 0.2mm |

| Min. Hole Size | 0.1mm |

| Min. Line Spacing | 0.2mm |

| Service | One-stop Service |

| Certificate | ISO, UL, SGS and ROHS |

Our Service

GTG PCB could provide one-stop pcb assembly service, including:

- Engineering Services.

- PCB Design & Assembly.

- Component Procurement & Material Management.

- Fast Track Prototyping.

- Cable and Wire Assemblies.

- Plastics and Molds.

If you need to design, layout, assembly PCB boards, or final product Assembly line, welcome to contact us.

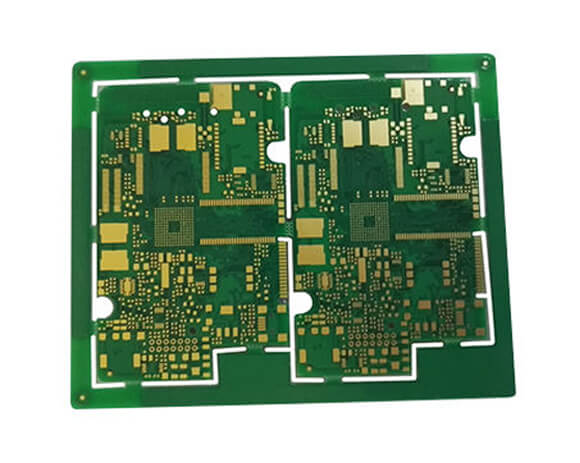

- High density. For decades, the high density of printed boards has grown with the increased integration of integrated circuits and advances in mounting technology.

- High reliability. Through a series of inspections, tests and aging tests, the PCB can be reliably operated for a long period of time (usually 20 years).

- Designability. For the various performances of PCB (electrical, physical, chemical, mechanical, etc.), the design of printed boards can be realized through design standardization and standardization, with short time and high efficiency.

- Productivity. With modern management, it can carry out standardization, scale (quantity), automation and other production to ensure product quality consistency.

- Testability. Established relatively complete test methods, test standards, various test equipment and instruments to detect and identify PCB product qualification and service life.

- Assemblyability. PCB products not only facilitate the standardized assembly of various components but also can be automated, large-scale mass production. At the same time, the PCB and various component assembly components can be assembled to form larger components and systems up to the complete machine.

- Maintainability. Since PCB products and various component assembly components are produced in a standardized design and scale, these components are also standardized. Therefore, once the system fails, it can be replaced quickly, conveniently and flexibly, and the system can be quickly restored. Of course, you can say more about it. Such as miniaturization and weight reduction of the system, high-speed signal transmission, etc.

We love hearing from our customers!

Simply fill out this online form and a PCB representative will get back to you shortly,within 24 hours.